1) Basic characteristics of machine tools

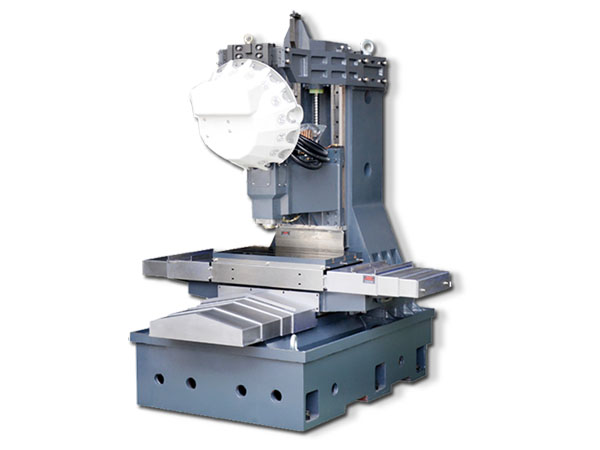

The machine tool adopts the latest finite element analysis system simulation and optimization design method. Through the overall optimization of the strength and stiffness of the machine tool, the machine tool achieves the best dynamic performance. It is the representative and mode of modular design and ergonomics design of international mechanical processing equipment, and put the machine tool workspace into practice. Fully play the role of optimization design in the field, and achieve a high degree of unity and harmony between human and machine. 2) General layout of machine tools

The design of direct connection between spindle and motor can output speed directly from motor shaft without transmission noise, backlash and belt vibration. The maximum speed is 2000/24 000/3 million rpm, and the maximum speed is determined by the sales contract. High quality tapping effect and surface brightness can be obtained. The main motor adopts low inertia and maximum motor. The acceleration time of 0-20 000/rpm is only 1 second. There is no time lag in high speed tapping and commutation to avoid tooth extraction.

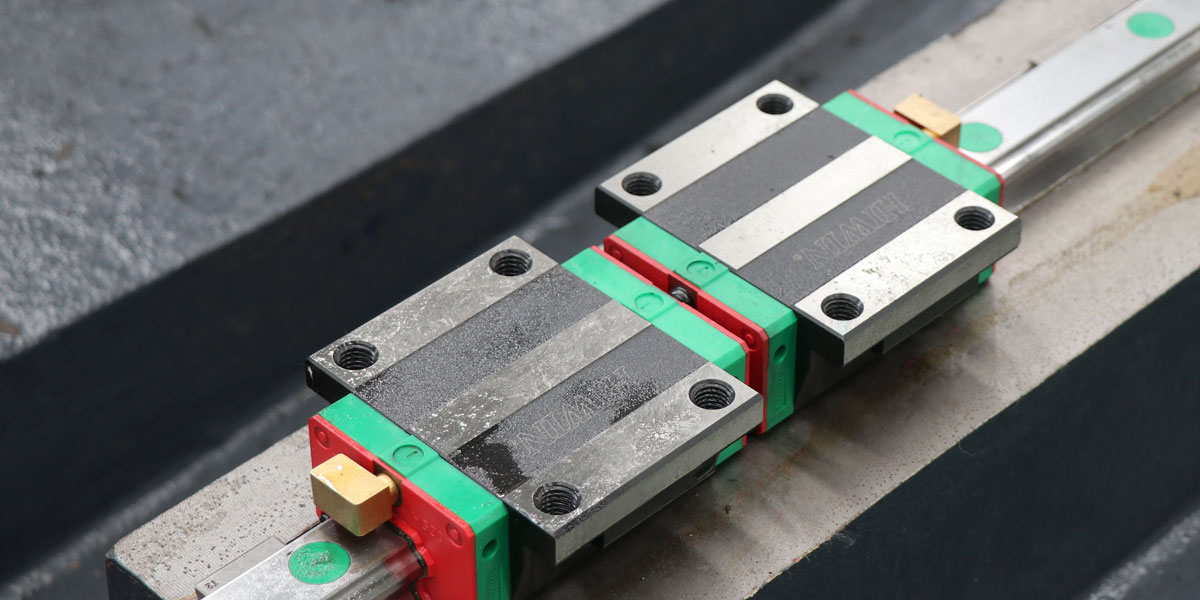

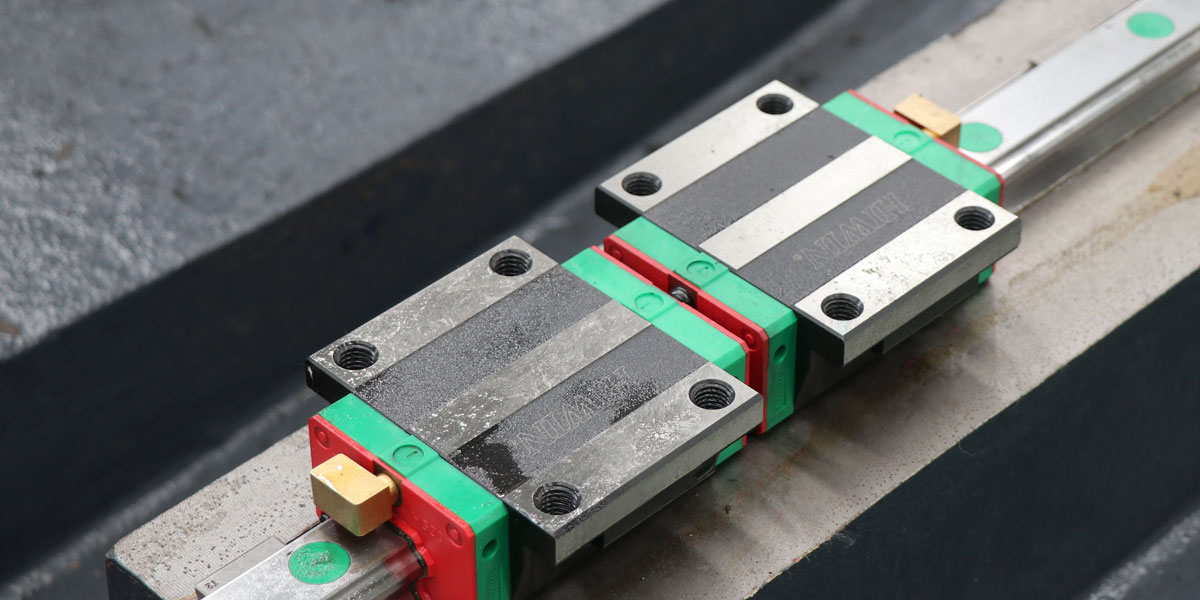

Linear slides are used for three-axis motion. The three axes can move quickly up to 48m/min, and can bear heavy load to ensure accurate positioning.

HT300 high strength inoculated cast iron is moulded with resin sand in machine tool base, worktable, column, cross beam, slide seat and spindle box. After secondary annealing treatment, the castings stress and internal stress produced by rough machining are completely eliminated, and the high stiffness, high stability and quality of the structure are guaranteed, and the quality is guaranteed permanently.

The finite element analysis method was used to calculate and analyze the castings. Reasonable structural strength and stiffener configuration can provide higher mechanical stiffness.

BT30-16T clamp tool library, tool replacement time 1.6 seconds.

3) Main Parts and Structures of Equipment (1) Base

Long-span base, effective dispersion of gravity and processing bearing capacity; short saddle overhang, greatly improve the dynamic accuracy;

(2) Columns

The herringbone column is more stable and rigid than the herringbone column, which can eliminate the problem of the left and right inclination of the column under lateral force to the greatest extent. The design of rice gold protection and chip removal system for Herringbone bed is more mature, and the leakage of sheet metal installation can be avoided from the mechanical structure.

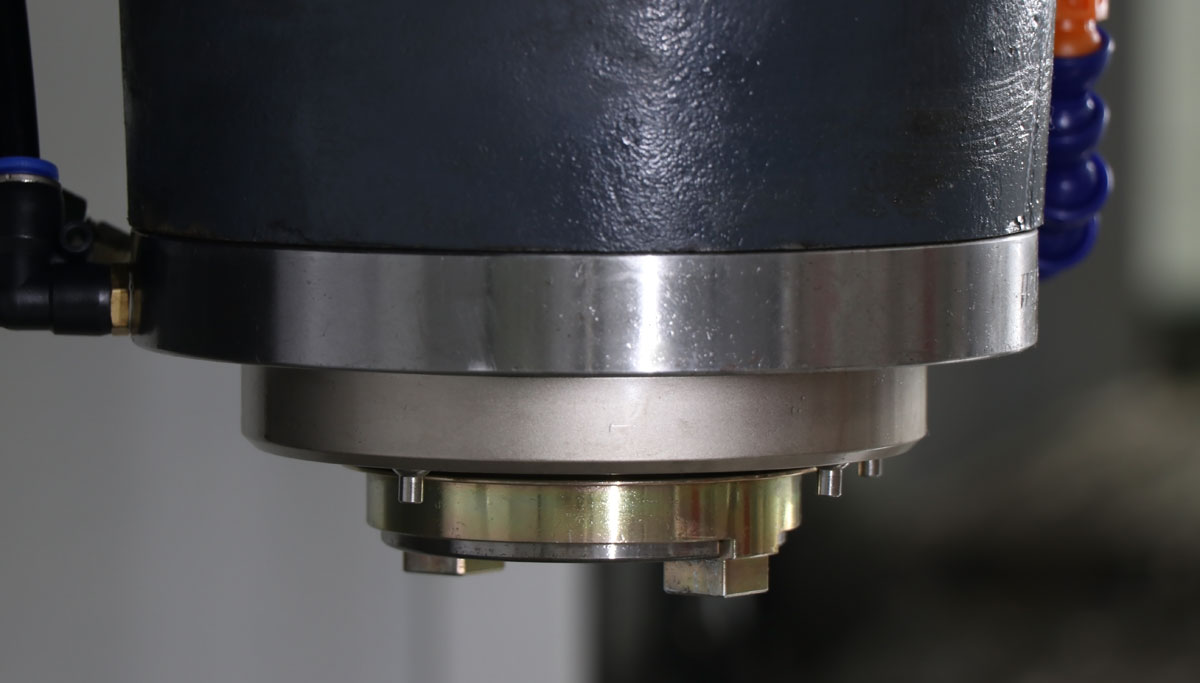

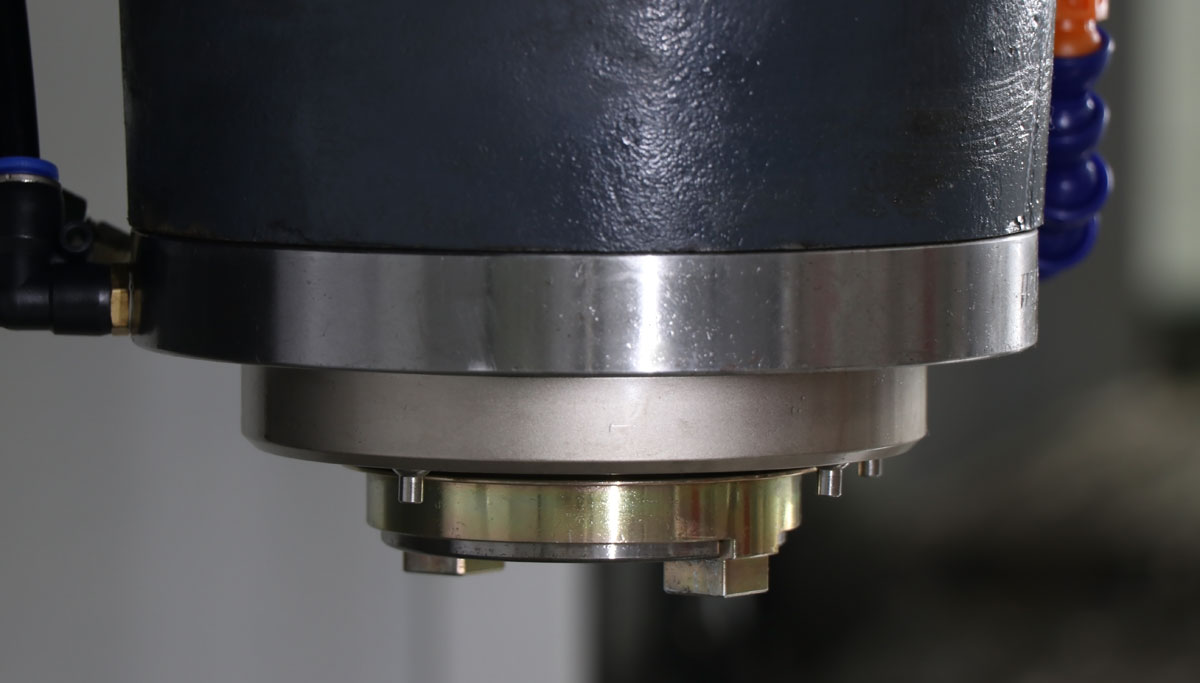

(3) Spindle box

The spindle box and pillar adopt the best contact ratio design to match the industry brand spindle, which achieves the high rigidity of the spindle unit of the huge machine tool.

(4) Precision spindle with high precision, high performance and high stability

The spindle manufactured by professional manufacturer has the characteristics of high speed, high precision and high performance. Standard 20000 spindle does not need to be equipped with an oil cooler to cool the spindle. It can be equipped with a circulating oil cooling system to reduce the temperature rise when the spindle rotates at high speed. In differential temperature mode, the temperature of the spindle is always lower than 2 degrees of room temperature, thus prolonging the life and accuracy of the spindle.

With low inertia spindle motor, the acceleration time is short, 0-20000 RPM only takes 1.5 seconds, the motor has high efficiency, fast acceleration and deceleration, direct connection reduces backlash problem, and improves the speed and quality of tapping teeth. The main shaft of direct connection transmission has no problem of noise and vibration of belt spindle.

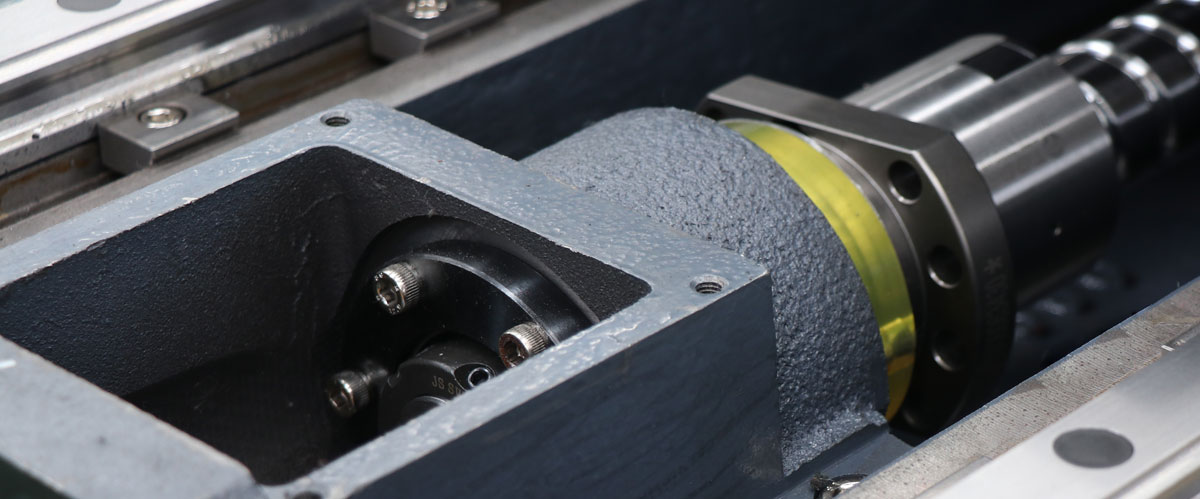

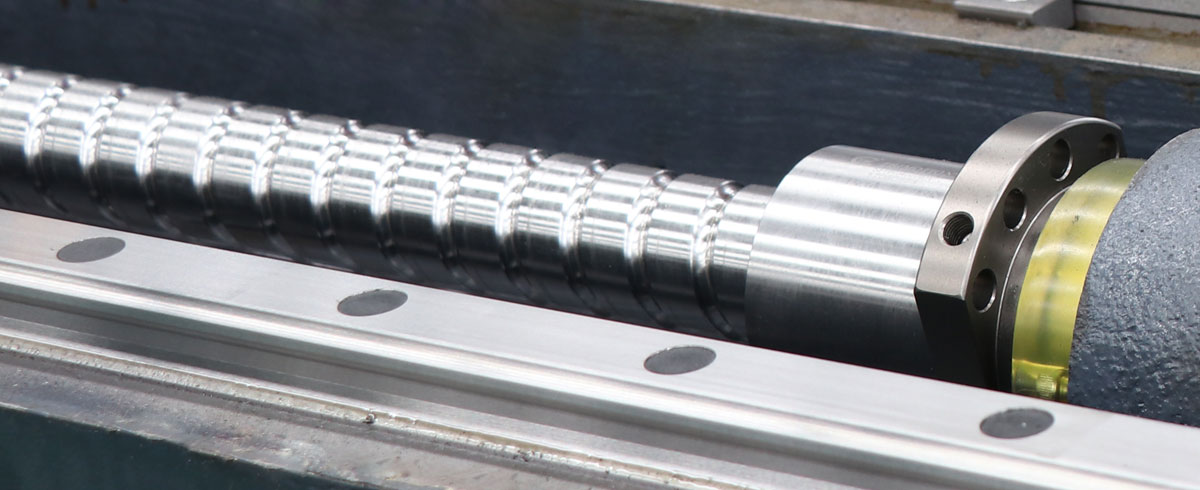

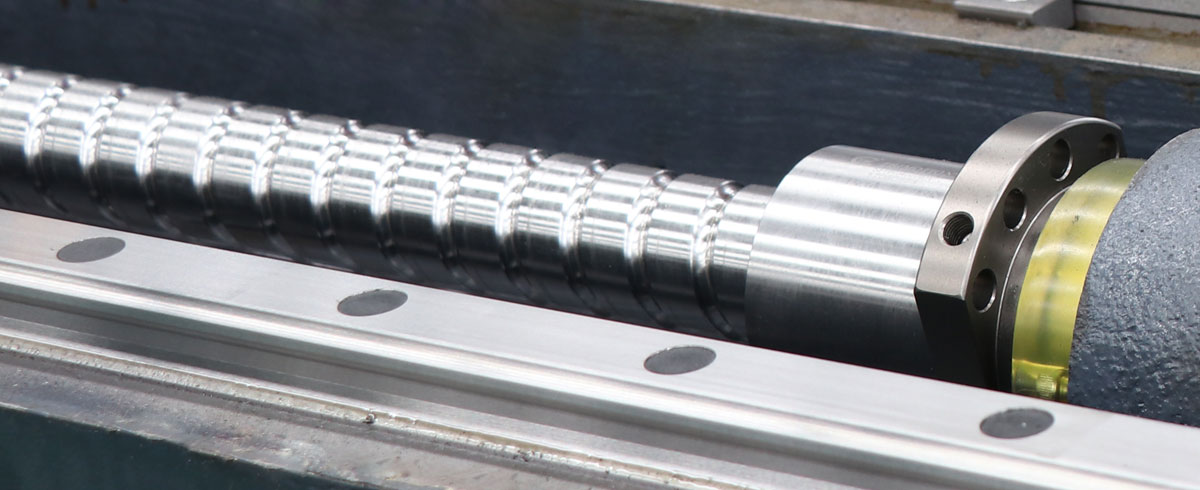

(5) Ball screw and linear slide

In order to ensure the rigidity and durability of the machine, the ball screw and linear slideway used in the series of drilling and tapping machining centers of giant high machine tools are more than 1.28 times larger than those used in the same industry, ensuring the maximum load and prolonging the service life of the machine.

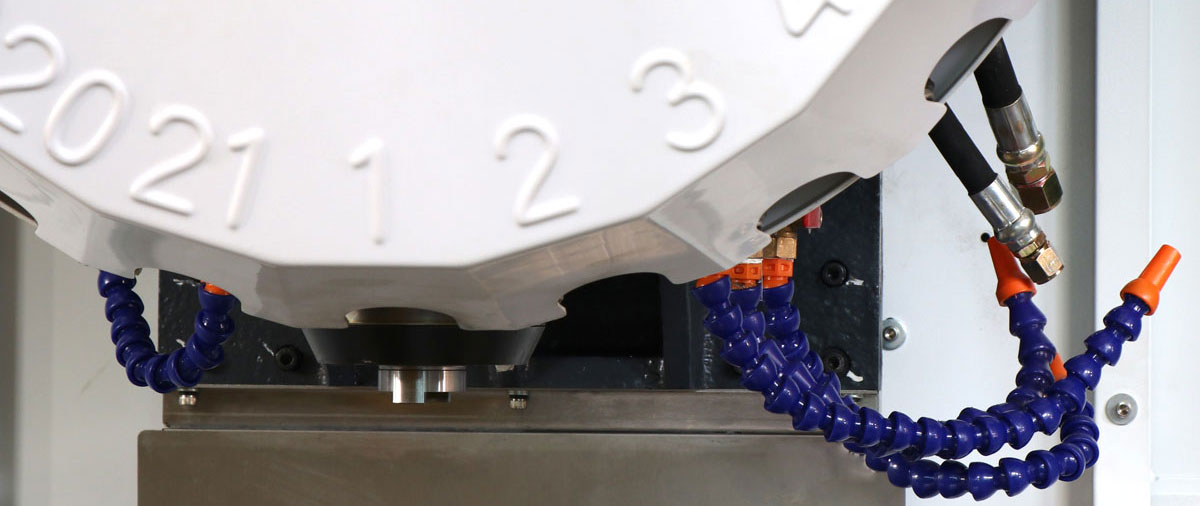

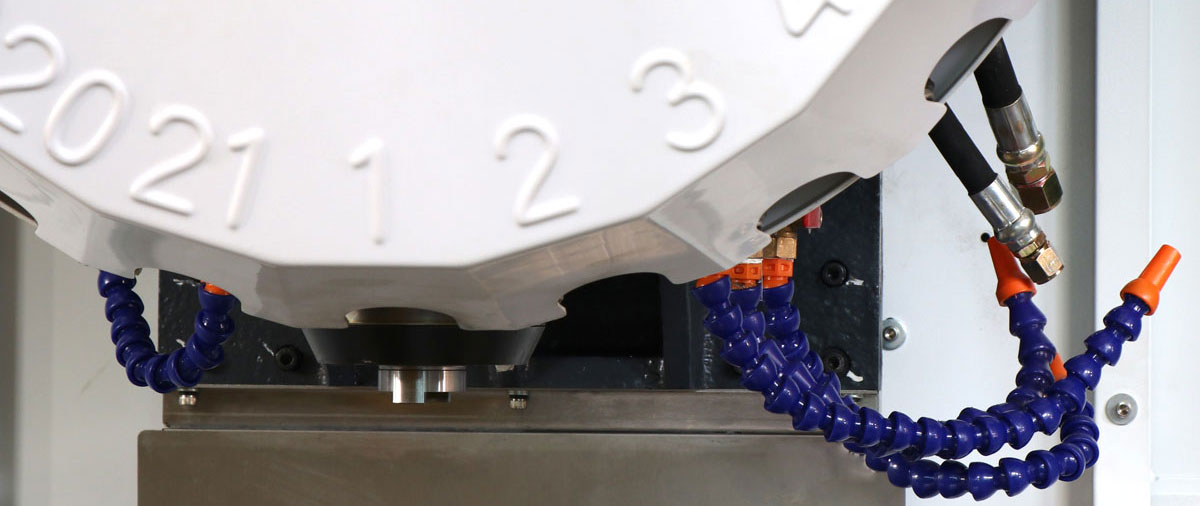

(6) Cutting cooling system

The machine tool is equipped with cooling system, and the perfect combination of large flow pump and many nozzles can effectively solve the machining malpractice of tool wear due to cutting overheating and workpiece deformation due to processing heating. (7) Machine Tool Protection

The machine tool bed guide (XY axis) adopts stainless steel telescopic and synchronous telescopic sheet metal; the pillar guide (Z axis) adopts organ and armor protection; and the machine tool adopts fully enclosed protection to prevent iron scraps and coolant splashing, so that the operator can work in a safe and comfortable environment.

(8) Appearance of machine tools

The appearance design of sheet metal of machine tool is simple and generous, and the sense of science and technology is abundant; the machine tool adopts super-high open door design, which changes the oppressive feeling of traditional drilling and tapping center because of its small size and very small sheet metal design; the super-large open door design not only makes the operator feel no narrowness when loading and unloading workpieces, but also has room for the entry and exit of the fourth axis. Super large water tank, large inclined angle chip removal trough, rear chip removal design, regardless of the maximum amount of cooling water will not stop flow, let alone cause machine tool leakage.

(9) Lubrication system Three coordinate bearings are lubricated by grease.

Ball screw and guide rail adopt automatic thin oil lubrication mode.

X, Y and Z coordinate guideways have automatic control lubrication points. Lubricating oil is separated to lubricate guideways.

Pressure detection method is adopted to ensure that the preset pressure can be reached every time the oil is pumped. Otherwise, the system prompts the alarm.

(10) Electrical part In addition to mechanical design, Giant High Machine Tool also pays attention to electrical design. CNC system uses unique optical fiber communication mode, which greatly improves the speed of data communication, greatly reduces the number of wiring, and makes the electrical cabinet more neat.

(11) Working conditions of machine tools

The requirement of power supply is three-phase four-wire system with 3_380V 50HZ.

Permissible Voltage Fluctuation Value of Power Supply: +10%

Permissible fluctuation value of power supply frequency: +1%

The machine tool must be grounded safely with a single cable and the grounding resistance should be less than 4 ohms.

Gas source: 0.4-0.6 Mpa

The ambient temperature range of the machine tool workshop is 10-35 C, the relative humidity is 40-75%, the atmospheric pressure is 86-106 Kpa, the dust concentration in the air should not exceed 10mg/m3, and the acid, salt and corrosive gas should not be contained.

The machine tool is installed far away from the source of earthquake, heat source and heat flow, and its vibration is less than 0.5G (G is gravity acceleration) workshop.

(12) CNC System

The product characteristics of CNC system are as follows:

Large plate structure has been used for a long time, but modular structure has been adopted in new products. Special LSI is adopted to improve integration, reliability, reduce volume and cost.

The product has a wide range of applications. Each CNC device can be equipped with a variety of control software, suitable for a variety of machine tools.

New technologies and technologies are constantly adopted. Such as surface mounting technology SMT, multi-layer printed circuit board, optical fiber cable, etc.

The volume of CNC device decreases and the panel assembled and built-in PMC programmable machine tool controller is adopted.

New functions have been added in interpolation, acceleration and deceleration, compensation, automatic programming, graphics display, communication, control and diagnosis.

Interpolation function: In addition to linear, arc, spiral interpolation, there are imaginary axis interpolation, polar coordinate interpolation conical interpolation, exponential function interpolation, spline interpolation and so on.

Automatic acceleration and deceleration function of cutting feed: in addition to linear acceleration and deceleration after interpolation, acceleration and deceleration before interpolation.

Compensation function: In addition to pitch error compensation and screw reverse clearance compensation, there are slope compensation linearity compensation and new tool compensation functions.

Fault Diagnosis Function: Artificial Intelligence is used, and reasoning software is used to find the cause of the fault based on knowledge base.

Handwheel is called hand artery impulse generator, also known as photoelectric encoder. Mainly used for CNC machine tools: vertical processing center, horizontal processing center, gantry processing center and other CNC equipment, such as novel shape, convenient movement, anti-interference, strong carrying capacity; all-plastic shell, high insulation strength, anti-oil pollution sealing design; with X1, X10, X100 triple rate, can achieve 4-axis rate switching; with control switch, emergency stop switch optional, human design, Easy to operate.